Unlocking Innovation: The Rise of Newest Engineered Precision Machining

Unlocking Innovation: The Rise of Newest Engineered Precision Machining Table of Contents 1. Introduction to Engineered Precision Machining 2. Historical Context of Precision Machining 3. Importance of Precision Machining in Modern Industry 4. Latest Technological Advancements in Precision Machining 5. Key Processes in Engineered Precision Machining 6. Applications of Prec

13

2025

/

01

Understanding the Benefits of Affordable Casting, Forging, and Machining in Manufacturing

In the manufacturing industry, particularly in the realm of mechanical hardware processing and component fabrication, the terms "cheap casting," "forging," and "machining" often surface. Understanding these processes and their benefits can be crucial for businesses looking to optimize production efficiency and cost-effectiveness. **Casting** is a process where liquid material is poured into a mold

10

2025

/

01

Top Considerations for Choosing Ductile Iron Machining Services: A Comprehensive Guide

Top Considerations for Choosing Ductile Iron Machining Services Introduction to Ductile Iron Machining Ductile iron, also known as nodular cast iron or spheroidal graphite iron, has garnered attention in various industries for its excellent mechanical properties. It combines the strength of steel with the castability of iron, making it a preferred material in sectors such as automotive, aerospace,

07

2025

/

01

Advantages and disadvantages of alloy steel casting

In conclusion, alloy steel casting offers a range of advantages such as high strength, wear resistance, and customizability, making it a popular choice for manufacturing components with specific performance requirements. However, there are also limitations and disadvantages to consider, such as size restrictions, porosity issues, and tooling costs, which may impact the overall feasibility of using alloy steel casting for certain applications.

11

2024

/

10

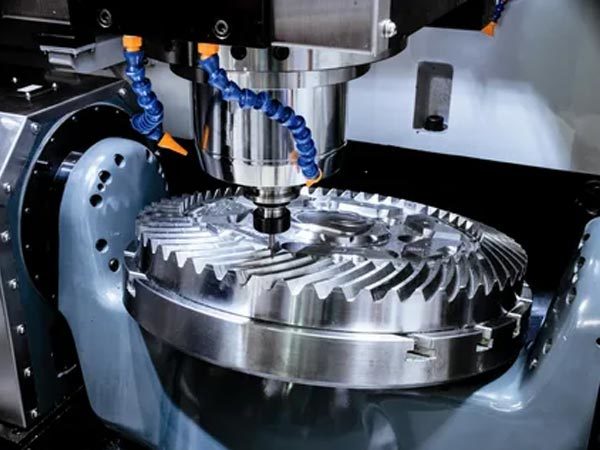

Characteristics of CNC milling

Complex geometries: CNC milling machines are capable of producing parts with complex geometries that would be difficult or impossible to achieve using traditional machining methods. This opens up new possibilities for design and allows for the creation of innovative and unique components.

11

2024

/

10

General steps of gear machining

Overall, gear machining is a precise and complex process that requires careful planning, skilled craftsmanship, and attention to detail to produce high-quality gears that meet the requirements of the application.

11

2024

/

10